Copyright © Alan Tani Reprinted with permission of the author.

Copyright © Alan Tani Reprinted with permission of the author.

With the US market flooded with TLD's, it's easy to think that the only graphite lever drag reels on the market belong to Shimano. Penn has had an excellent line of graphite trolling reels for years. Starting with the KG series, and now the GLD's, the only complaint I’ve heard has been the overall larger size of this reel versus the TLD's. It’s different inside. Here’s are links to the schematics.

GLD 30 Schematics and Parts

GLD 20 Schematics and Parts

and here is our reel:

One of the interesting things about this reel is the material used for the lugs, quadrant, handle arm and some other parts. According to my machinist friend, these are all stainless steel.

Remove the side plate screws (key #16) and quadrant spacer bushings (key #157a).

Removing the quadrant ring (key #2) is the hardest part of this rebuild. You have to push in on the free spool button (key #161) and the strike button (key #161a) at the same time. Then you have to push the quadrant ring (key #2) up and over to the right. It's a tight fit. Work it and you'll get it out.

Flip the reel over and remove the lower frame screws (key #46a).

Remove the long frame screws (key #31) and short frame screws (key #46).

Let's set them aside so they don't get lost.

Remove the right side plate and spool as a unit.

Unscrew the preset knob (key #144).

The spool assembly separates easily from the right side plate assembly. Set both aside.

Here's the clicker assembly (key #35, et.al.). Nothing to service here.

Back out the left side plate screws (key #46b), add a little grease to the threads and zip them back in.

This reel was shipped without a rod clamp, but we're going to grease the threads anyway.

OK, the frame is done. Let's set it aside and move on.

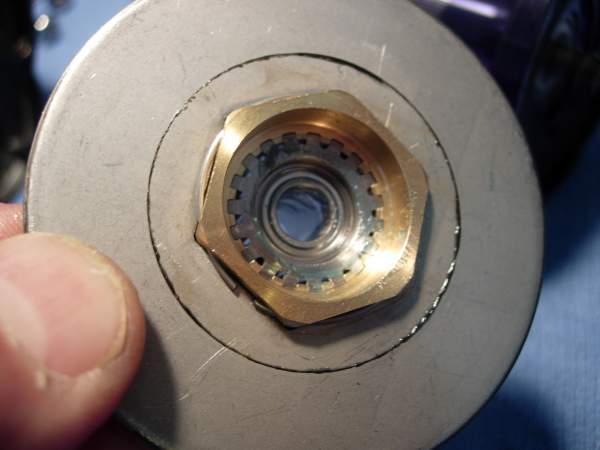

To service the spool, let's first remove the drag cover (key #156). The threads are left handed.

Remove the drive plate (key #117). There is a bearing inside that we will get to later.

Remove the spindle spring (key #41).

Remove the spindle retaining ring (key #69c).

Pull the spool spindle (key #71). Four disc clutch springs (key #18) come out with the spool spindle. Note the "()()" orientation.

Remove the left spool bearing (key #26a). This bearing measures 7x22x7.

Remove the four ratchet screws (key #101) and the click ratchet (key #81).

Remove the left spool bearing (key #55). This bearing measures 10x26x8.

I’ve added the two bearings to the spool spindle. Note that the spindle is turned down 7mm to accommodate the right spool bearing. It functionally serves as a bearing sleeve.

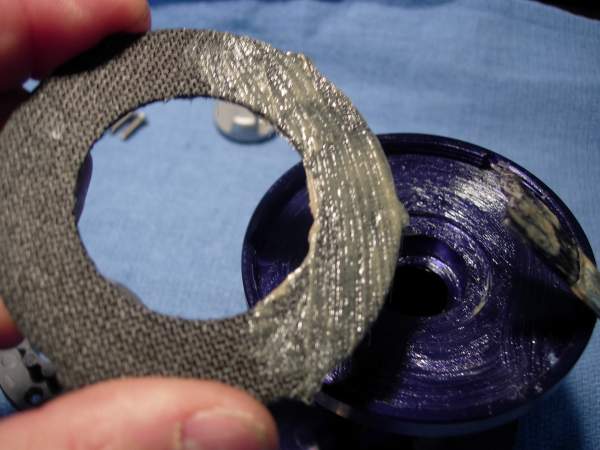

Flip the spool around and remove the drag washer (key #6). Interestingly, there appears to be a coat of grease on both the drag washer and the spool underneath.

Since we don't know what is on the drag washer already, let's go ahead and give the spool (key #29) a light coat of Cal's grease.

aAdd a light coat of Cal's grease to both sides of the drag washer (key #6).

Install the greased drag washer (key #6) into the spool (key #29).

Wipe off all of the excess grease from the working surface of the drag washer (key #6).

Hmmm..... doesn't loOK a bit different.

Now for the bearings. If you haven't seen it before, take a loOK at the old post on how to crack open and service a bearing at http://alantani.com/index.php?topic=13.0. This bearing is partially greased. We are going to clean out the left spool bearing (key #55) and lube it with Xtreme reel +.

Here's the inside of the right spool bearing (key #26a). I’ve seen this grease in some of the older international bearings before. It has the consistency of peanut butter that has been left out for a week.

Here we go. Both spool bearings, cleaned with carb cleaner and compressed air, lubed with Xtreme reel +, and ready to go.

Now what we are going to do is to "blue print" this reel. If you're not familiar with this procedure or the theory, take a loOK at this post. Http://alantani.com/index.php?topic=138.0. Now, every week or so, I sweep the floor around my work area. Over the years, this is the junk that I’ve accumulated.

In this box are several dozen left over 7mm ID flat thrust washers used in the Shimano TLD 20/30 two speed reels. The part # for these washers is #TT-0042A and they are available from Shimano USA by calling 1-877-577-0600.

We are going to add these 7mm washers to the spool spindle (key #71) to build up a functional "bearing sleeve."

Install the new "blue printed" spool spindle. We ended up needing seven of these washers. Remember that a piece of paper is 3 thousandths of an inch thick. I’m guessing that our "sleeve" is 5-6 thousandths too long, which should work just fine.

Install the right spool bearing (key #26a) and the spindle retaining ring (key #69c).

The bare spool spins for 60 seconds.

Install the spindle spring (key #41).

Remove the drive plate bearing (key #20) from the drive plate (key #117). This bearing measures 7x13x4.

Carefully remove the retaining rings and shields. This bearing was not greased at all inside. Pack it with grease, reinstall the shields and retaining rings, and reinstall the bearing back into the drive plate.

Install the drive plate (key #117).

Install the drag cover (key #156) and remember that it has left hand threads. The spool is now done. Set it aside and let's take a loOK at the right side plate.

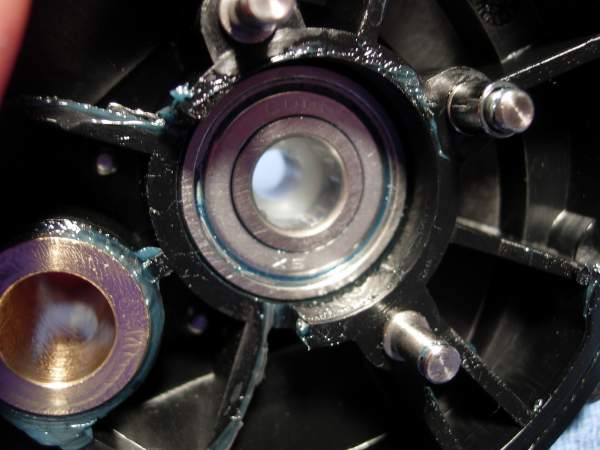

For the right side plate, there is only one thing that we need to do. We need to remove the right spool bearing, pack it with grease, and put everything back together. This will be the trickiest part of the rebuild, but it is absolutely necessary. The right main side plate bearing is always the first one to fail.

Remove the three retaining clips (key #69b).

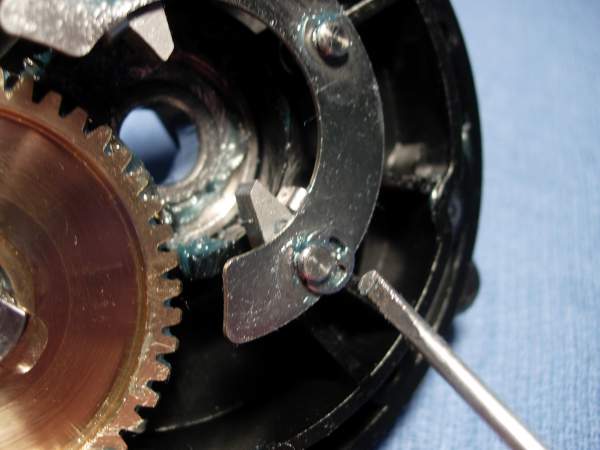

Remove the dog bridge (key #3).

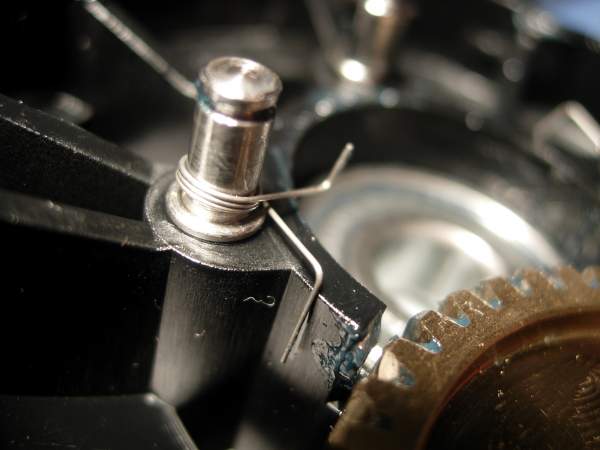

Note carefully the position of the dogs (key #15) and the dog springs (key #14).

Remove the dogs (key #15).

Remove the dog springs (key #14).

Remove the handle lock screw (key #110).

Remove the handle locking plate (key #110a).

Remove the handle screw (key #23).

Remove the handle (key #24).

Remove the gear stud shield (key #50).

Remove the gear stud retaining ring (no key #).

Remove the gear stud (key #134) and the main gear (key #5) as a unit.

OK. Now, FINALLY, we can remove the right main side plate bearing (key #55).

This bearing measures 10x26x8. It is only partially greased.

Let's pack it with grease and reinstall the shields.

Install the bearing (key #55) back into the right side plate (key #1).

Install the gear stud (key #134) and main gear (key #5) as a unit.

Install the gear stud retaining ring (no key #).

Install the gear stud cover (key #50).

Install the handle (key #24).

Install the handle screw (key #23).

Install the handle locking plate (key #110a).

Install the handle lock screw (key #110).

Install the dog springs (key #14).

Install the dogs (key #15).

Install the spacer bushing (key #157). This was not shown during disassembly.

Install the dog bridge (key #3).

Install the retaining rings (key #69b).

Install the preset knob bushing (key #26).

Install the preset knob (key #144).

Install the spool and right side plate into the frame.

Install the right side plate screws (key #'s 31, 46, and 46a).

Install the quadrant ring (key #2), the spacer bushings (key #157a) and side plate screws (key #16).

Done! This reel was spooled up with 300 yards of 60# Berkeley big game. The stack of bellevilles was then changed from "()()" to "))))))" to bring the drag range up to 20 pounds of drag at strike before losing free spool. At this drag setting, the reel only had 30 seconds of free spool. There was a rub somewhere that I could not find.

Now for a few comments. I think it would be fair to compare the Penn GLD 30 to the Shimano TLD 25. They both have the same spool capacity as the 4/0-sized Penn 113hlw and will hold the same 300 yards of straight 60# Berkeley big game. They both have a graphite frame, which I believe limits both reels to 20#'s of drag at strike to avoid the risk of catastrophic frame failure. Both reels are rated for a maximum of 17 pounds of drag at strike while still maintaining free spool. I have personally found that the TLD 25 delivers drag settings as low as 12 pounds before losing free spool. Still, the manufacturers both rate their reels to 17 pounds.

I think the Shimano TLD has several advantages over the Penn GLD. I find that it is easier to increase the drag range and it has better free spool. I had some difficulty getting the spool of the GLD to spin well when it was inside the frame. It is also much easier to reach the bearings, and it's not just because I’ve worked on so many of them. Here are fewer steps required to service the bearings in the Shimano TLD.

I think the Penn GLD has several advantages over the Shimano TLD. The Penn GLD comes with a carbon fiber drag washer and it may already be greased. The Shimano TLD 25 drag washer is canvas and really HAS to be replaced. The quadrant, preset knob and many other parts of the GLD are stainless steel and will not corrode easily. The chromed brass pieces of the Shimano TLD are well known to corrode over time. The handle arm on the Penn GLD is plenty long and the grip is very beefy. The handle on the Shimano TLD 25 is so short and stubby that it borders on ridiculous. The gears and bearings are much larger in the GLD, but I but this does not necessarily mean increased performance. The Penn GLD has two anti-reverse dogs that lock up against the spool shaft. This compares to the single anti-reverse dog for the Shimano TLD that locks up against the main gear shaft. using the main gear as part of the anti-reverse mechanism is what damages the main and pinion gears in the Shimano TLD. The GLD frame is bulkier, but I am not certain that it necessarily translates into more strength.

A quick check at tackledirect.com gave me a price of $220 for the GLD 30 and $180 for the TLD 25. I highly recommend servicing the bearings prior to fishing with both of these reels. The total cost for this service will range from $40 to 60. After that, you should be able to fish with Penn GLD with confidence for years to come. The Shimano TLD is another matter. In additional $40 minimum service, I would also recommend a $19 Carbontex drag washer upgrade and a $40-60 handle upgrade to bring the Shimano TLD 25 up to par with the Penn GLD. When I service a Shimano TLD 25, the minimum charge is nearly $100 to service the bearings, install a bearing sleeve, upgrade the drag and upgrade the handle. In the final analysis, the GLD will cost more at the tackle shop, but comes in as less expensive when you consider the total cost of available upgrades. After these upgrades are completed, the performance of these two reels should be the same. Straight out of the box, you can anticipate bearing and drag issues with both reels somewhere down the line, but I believe that the Penn GLD will initially far out perform the Shimano TLD.

Copyright © Alan Tani Reprinted with permission of the author.

Order parts online for this reel(s):

https://www.mysticparts.com/PennParts/Conventional.aspx#GLD

0 Comments