Copyright © Alan Tani Reprinted with permission of the author.

Copyright © Alan Tani Reprinted with permission of the author.

Here's a real gem. Not many of them left. They are still used by northern California salmon fishermen to drag 2.5 pound lead balls on sinker releases. The low gear ratio makes this reel well suited for that purpose.

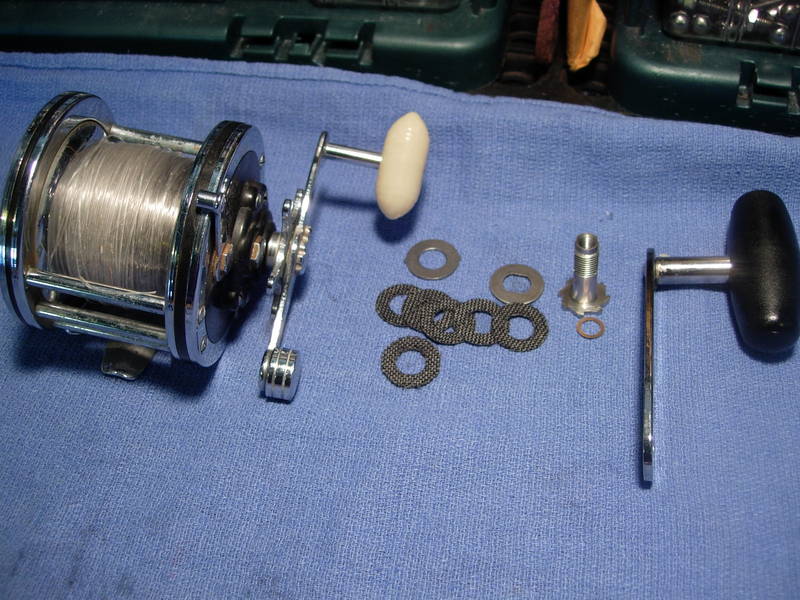

This particular reel still has the original handle, a brass gear sleeve and a stack of three old drag washers. What I'm going to do is install a new stainless steel gear sleeve from mysticparts.com, a Penn Jigmaster power handle and I'm going to change the drag stack from "1+3" to "1+5". the greater number of drag washers will deliver more drag range and the stainless steel gear sleeve and larger handle will allow us to crank under this heavier load.

If you are considering a full conversion like this, bear in mind that you will have to dremmel out the side plate a little. If you wish to simply upgrade the drag to a "stock" configuration, you will need a fiber washer under the gear (part #4-60) and three carbon fiber washers inside the gear (part #6-113). Our full upgrade requires one #6-113 drag washer under the gear, five #6-60 drag washers inside the gear, a full set of five #7C-60 metal washers, a #24-56 jigmaster power handle, a #98-60at stainless steel gear sleeve, and, most importantly, and couple of extra #14-99 dog springs. Go here for a schematic and a list of parts.

111 Schematic and you can order parts here: https://www.mysticparts.com/PennParts/Penn111.aspx

ok, let's crack it open. Start with the left side plate screws (key #'s 39 and 39a). Remove the left side plate (key #27).

Note the different length of the bottom screw (key #39a).

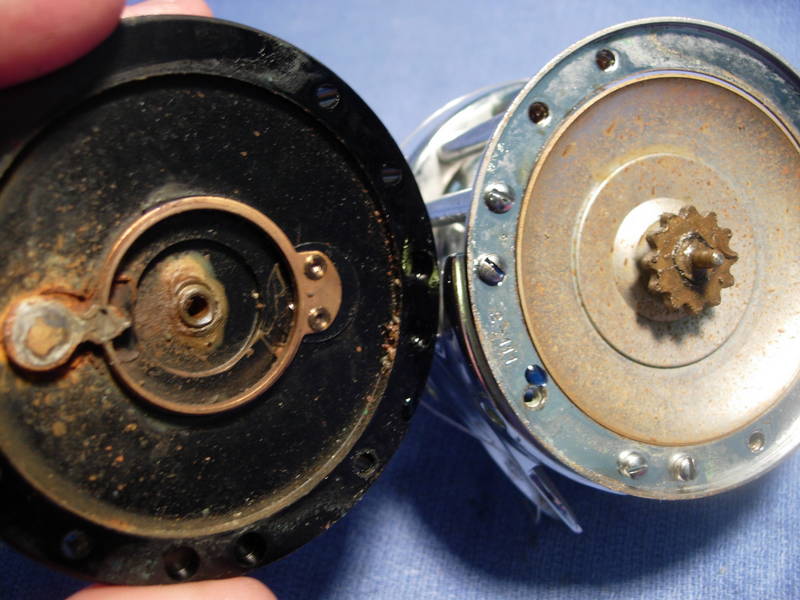

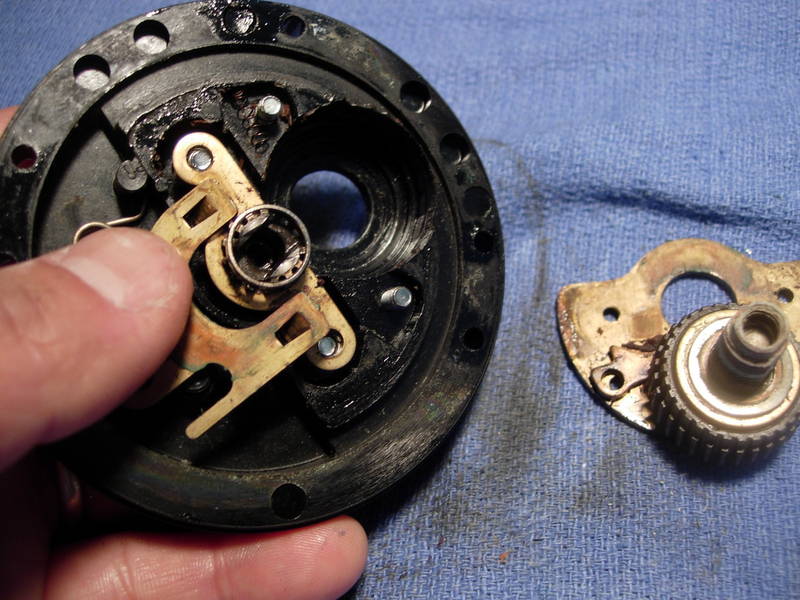

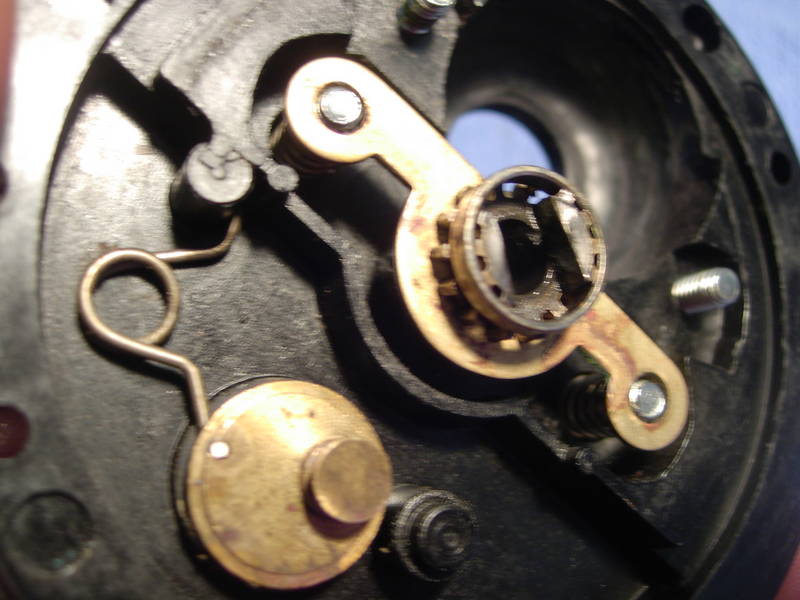

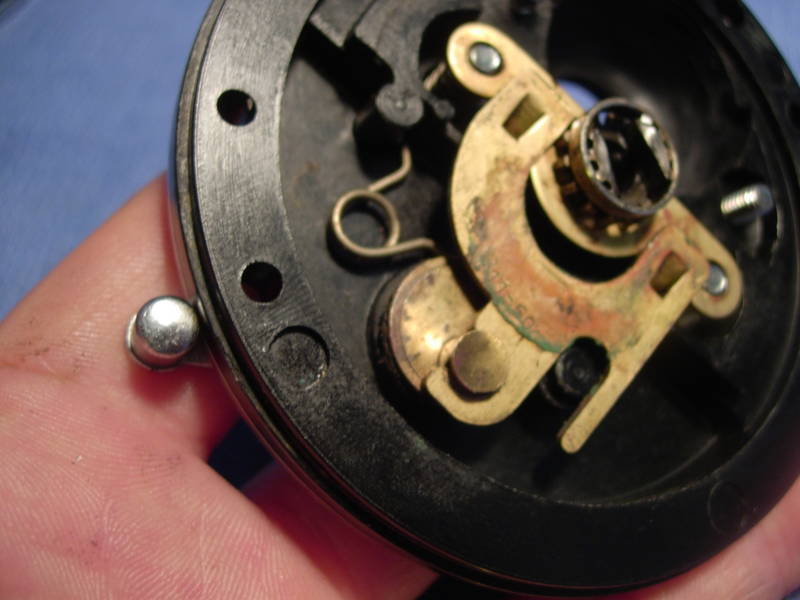

The clickers of these older reels are riveted in and they rust. It really makes a mess.

The rust gets everywhere.

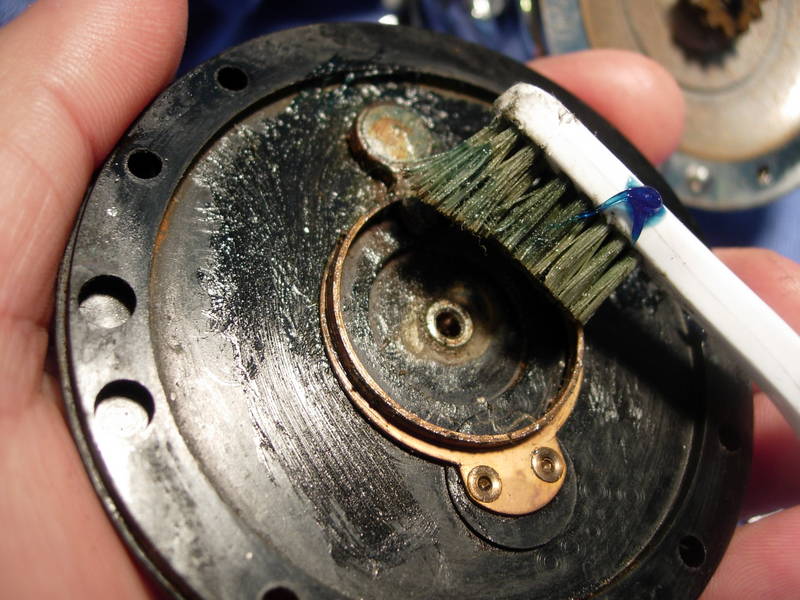

Normally what I'd do is throw everything into the ultrasonic cleaner for a couple of hours. That won't help you, so let's just clean it up with an old toothbrush and a little grease.

A little yamaha elbow grease works works wonders.

Same with the chrome-over-brass spool (key #29).

There! Big improvement and it now has a light coat of grease that will slow down further corrosion.

Take a moment to clean up the stand (key #30) and frame posts (key #37).

Let's back out, grease and reinstall the inner stand screws (key #38a) and inner post screws (key #32).

Reinstall the left side plate (key #27) and screws (key #'s 39 and 39a).

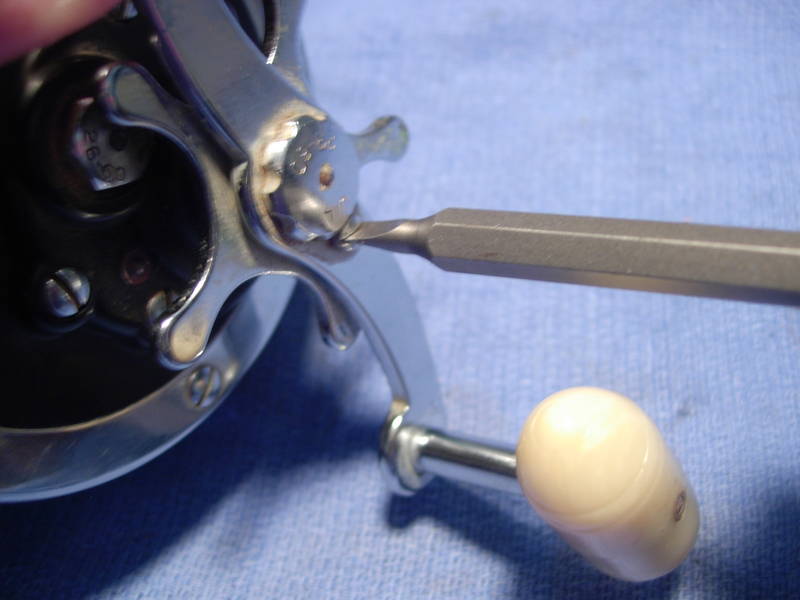

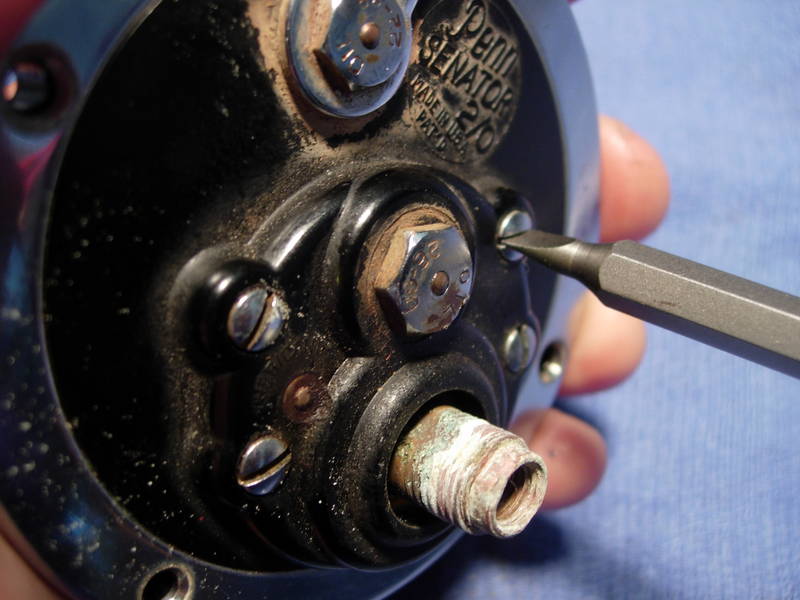

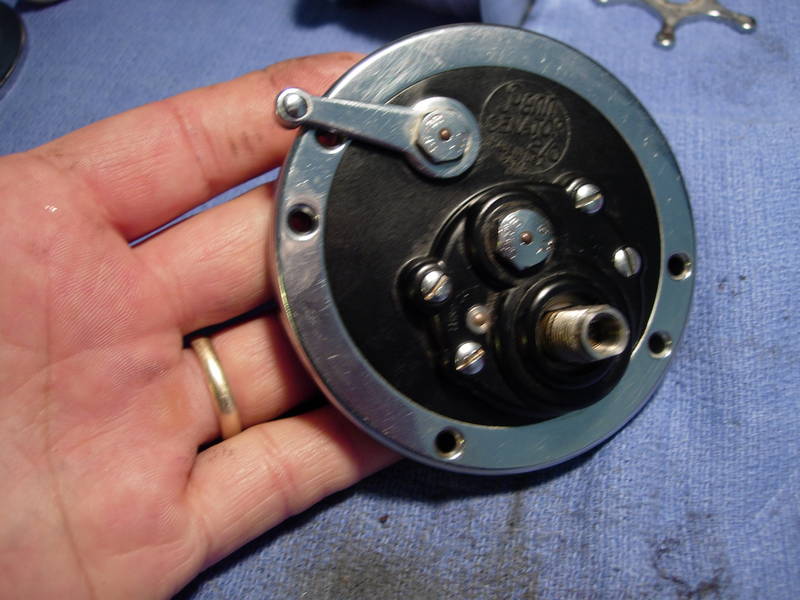

Now for right side. Let's remove the handle first. Start with the handle lock screw (key #23a).

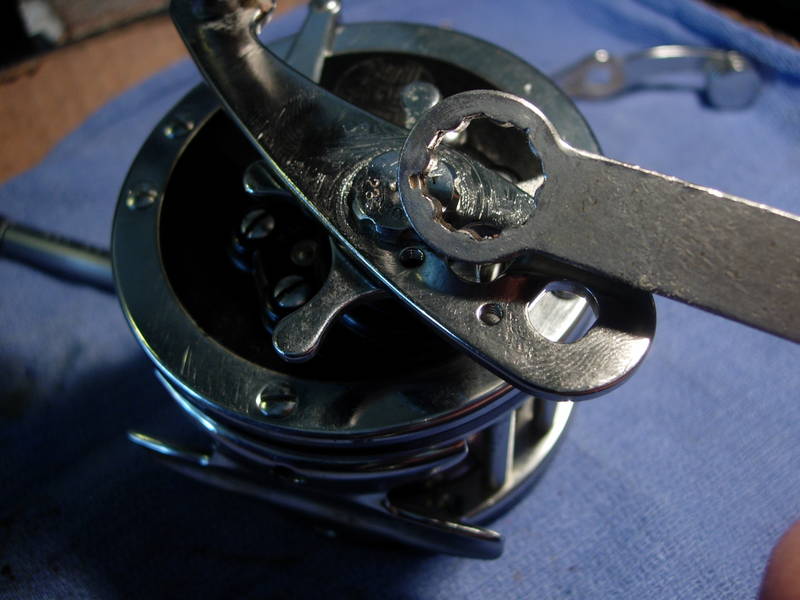

Remove the handle screw (key #23). I had a custom wrench made a while back.

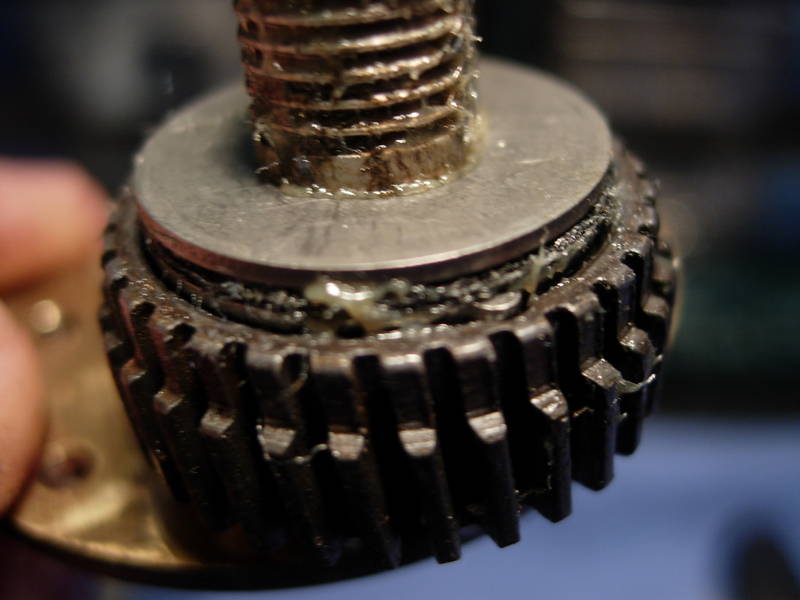

Been a while since this reel had been serviced.

Remove the handle (key #24).

Remove the star drag wheel (key #10).

Remove the spacing sleeve (key #9).

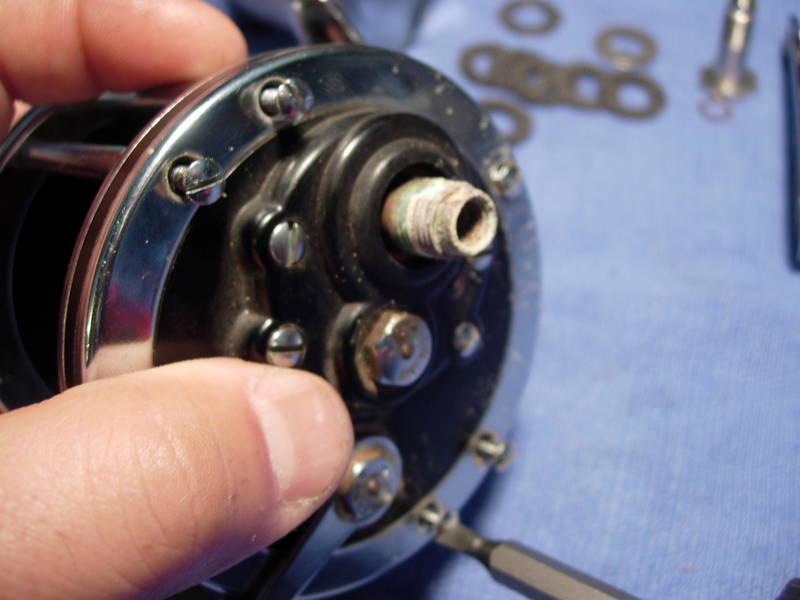

Remove the right side plate screws (key #'s 31 and 38).

Again, note that the center screw (key #31) is shorter.

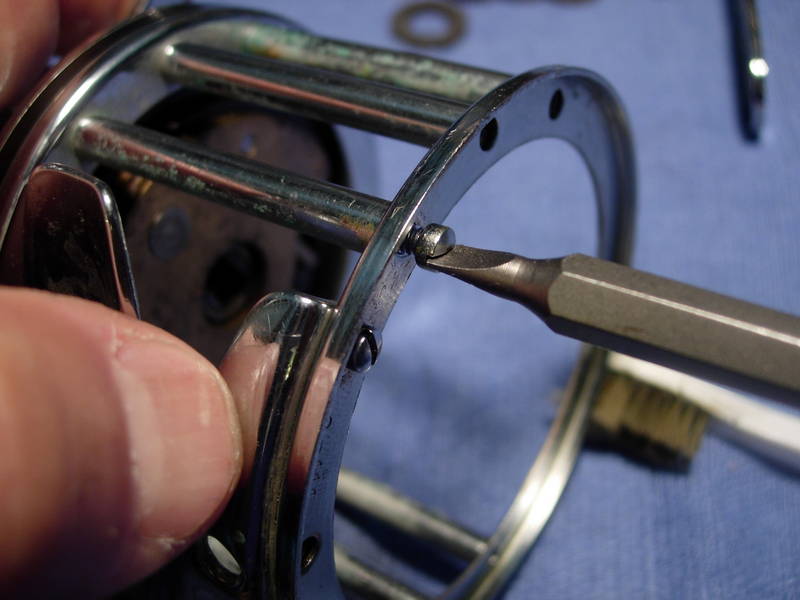

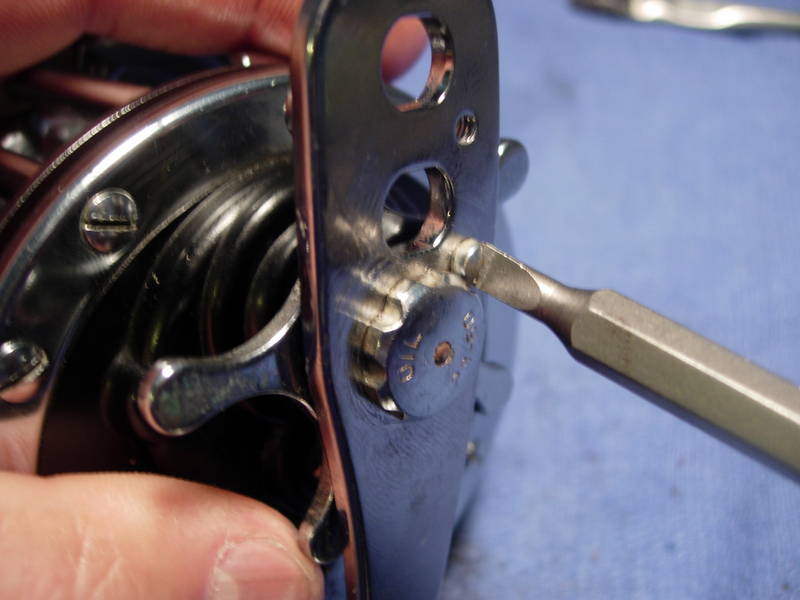

If you have trouble removing the side plate, try tapping around the inside lip with a small swiss army knife.

Remove, grease and reinstall the right inner frame screws (key #32) and right inner stand screws (key #38).

Let's take the opportunity now to brush things up a little.

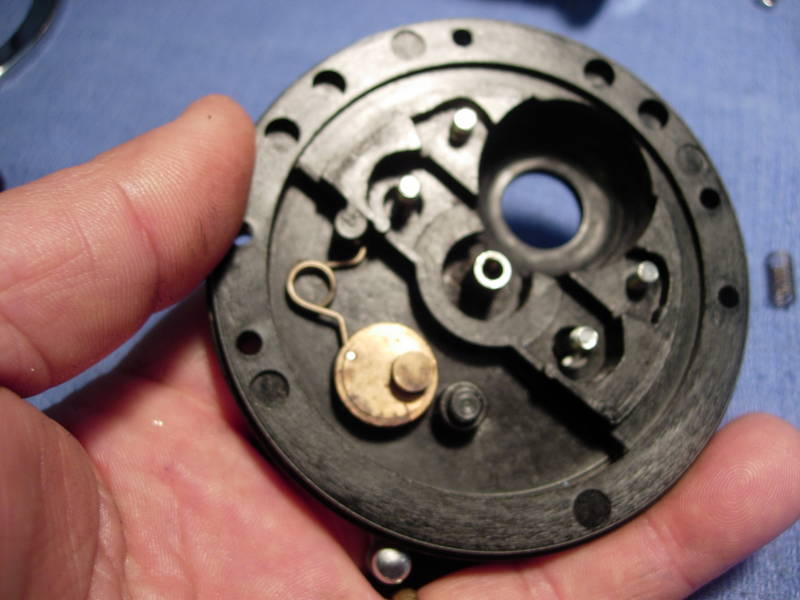

Remove the lower (key #16) and upper (key #17) bridge screws.

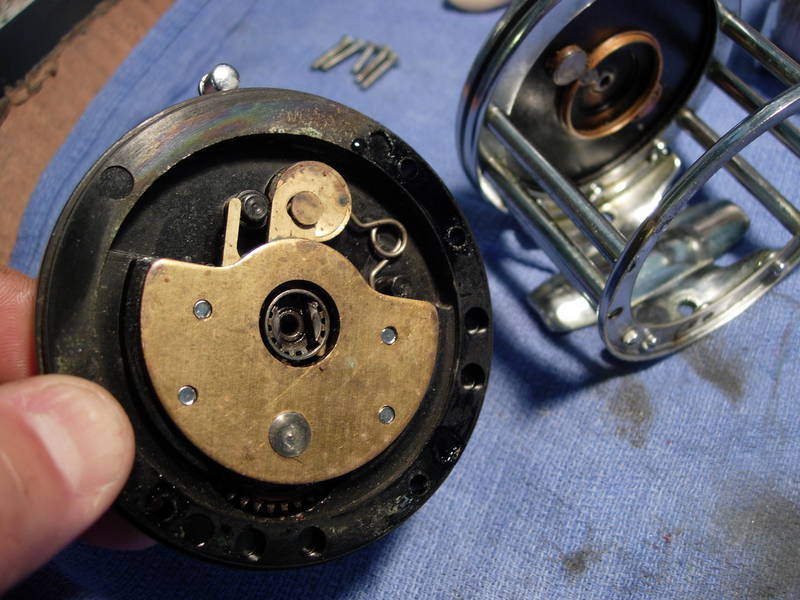

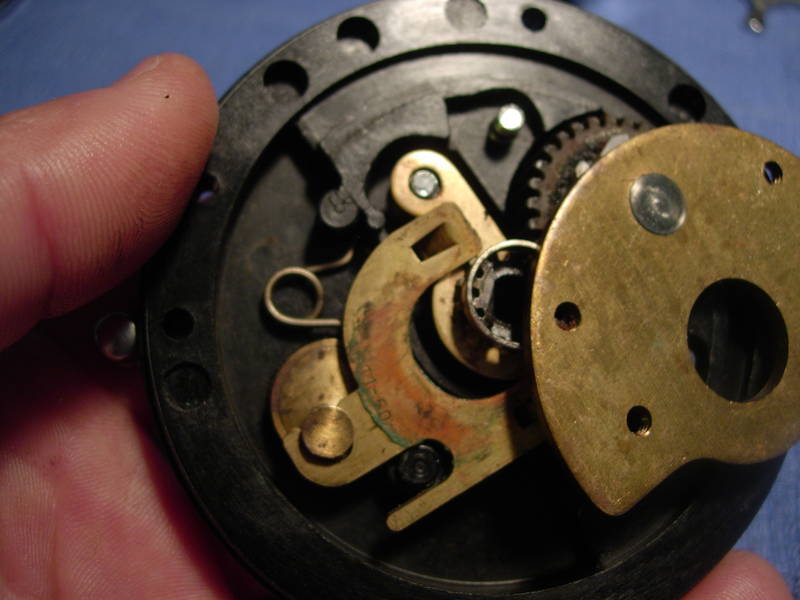

The bridge assembly (key #3) should simply fall out.

The first thing you are looking for is the dog spring (key #14).

find the dog (key #15).

Set them both aside, someplace safe.

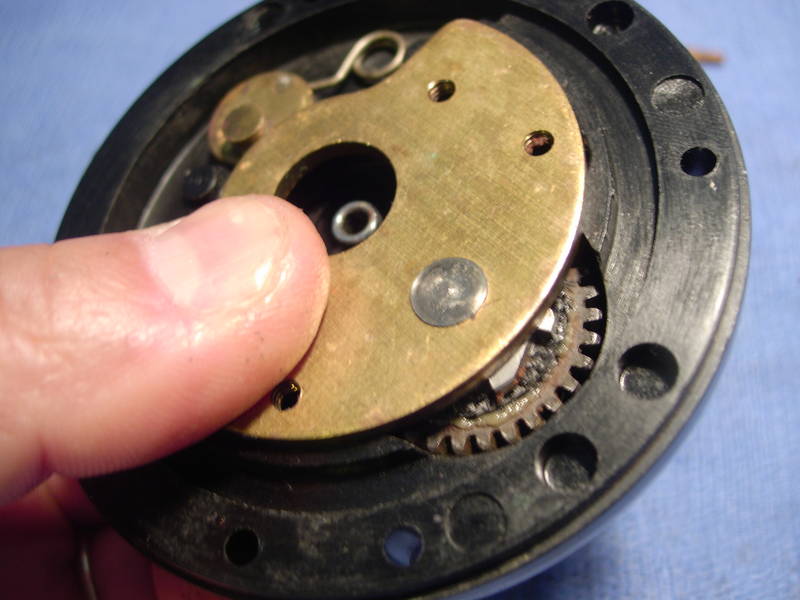

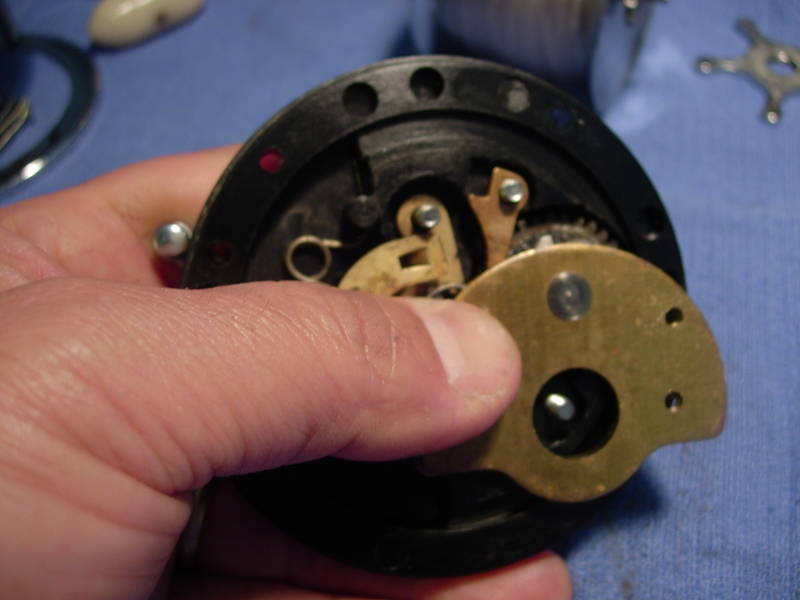

Now for the bridge assembly (key #'s 98 and 3-8).

If you have trouble removing the main gear, try giving the flat sides of the gear sleeve (key #98) a couple of strokes of a flat file. This usually works.

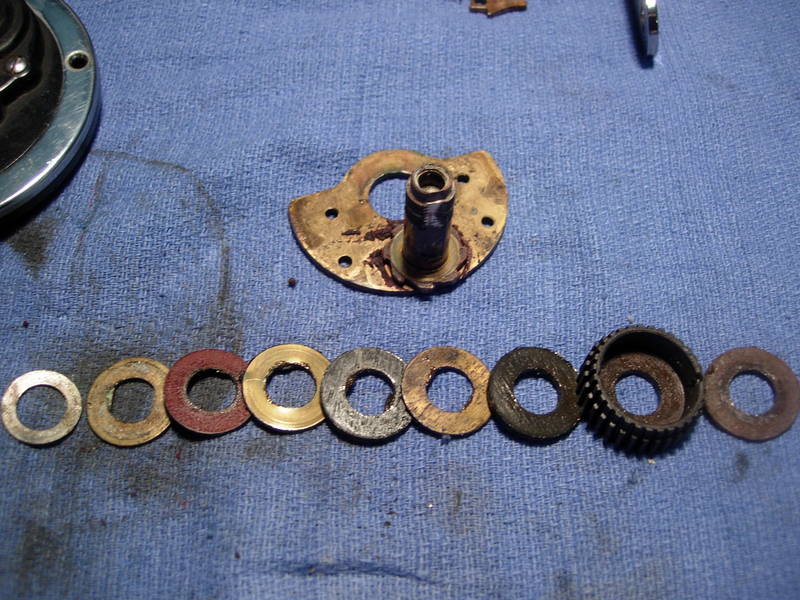

The drag stack was pretty much fused together. Only one metal drag washer was functioning. Yeah, it was the shiny one.

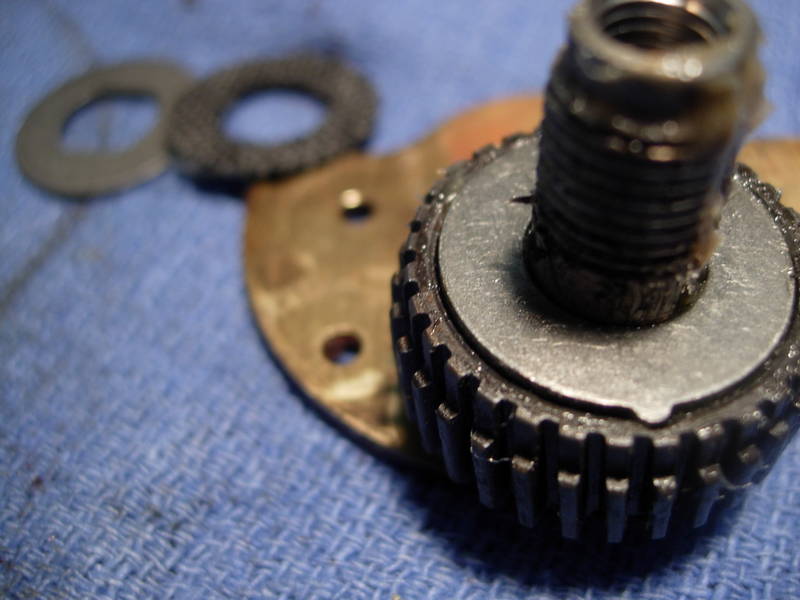

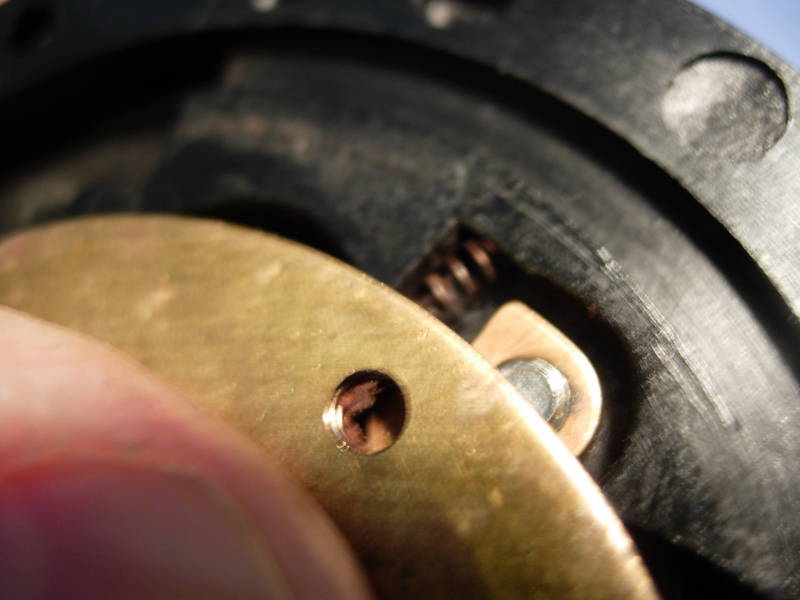

We need to punch out the brass pin holding the gear sleeve in. A small punch works well for this. some can just be pushed out, some need to be hammered. All i did was lean on this one and it slid right out.

Corrosion X (in a Reel X bottle) works well here.

Install the new stainless steel gear sleeve (part #98-60 at). Channel locks work well to press the pin in. If the pin sticks out a little, a flat file can easily take off the edge.

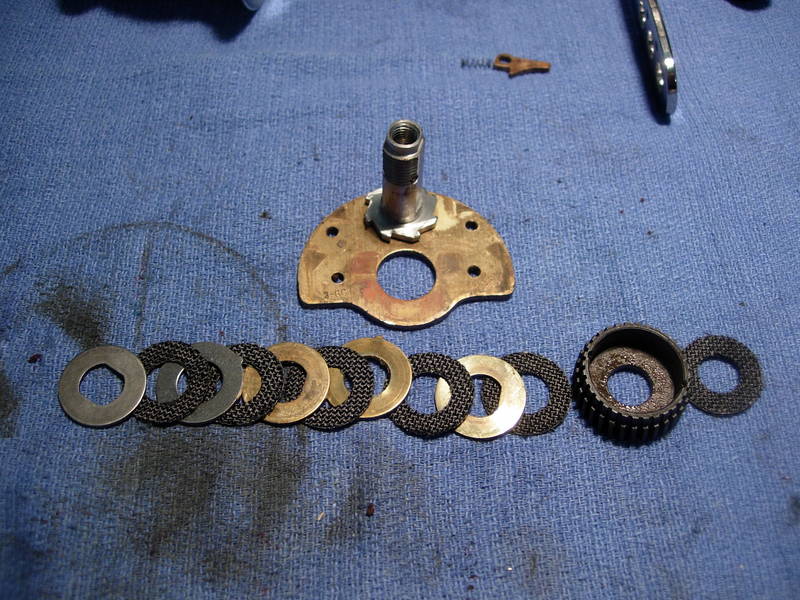

Here's the new line up. I've added an extra pair of metal washers. They alternate keyed, slotted, keyed, slotted, keyed. In between the metal washers go a set of five #6-60 penn ht-100 drag washers. underneath the main gear (key #5) goes a #6-113 drag washer. This is the combination that I've found will give the best performance.

Slap a thick coat of cal's drag grease on each drag washer and rebuild the stack. Don't worry about the excess. It will just squeeze out the sides.

Here's the fourth slotted metal washer. note that it has to nest inside the gear and it barely fits. This is fine as long as you get full drag range. If this metal washer rides up and rotates a few degrees, it will sit on top of the gear. The star will not travel as far when turned down and you will only get a few pounds of drag.

The last carbon fiber washer and metal keyed metal washer sit above the lip of the main gear. No problem.

When you put some pressure on the drag stack, it squeezes right down. We're done here. Let's set it aside.

The toothbrush (and the dental pick) are getting a real workout today.

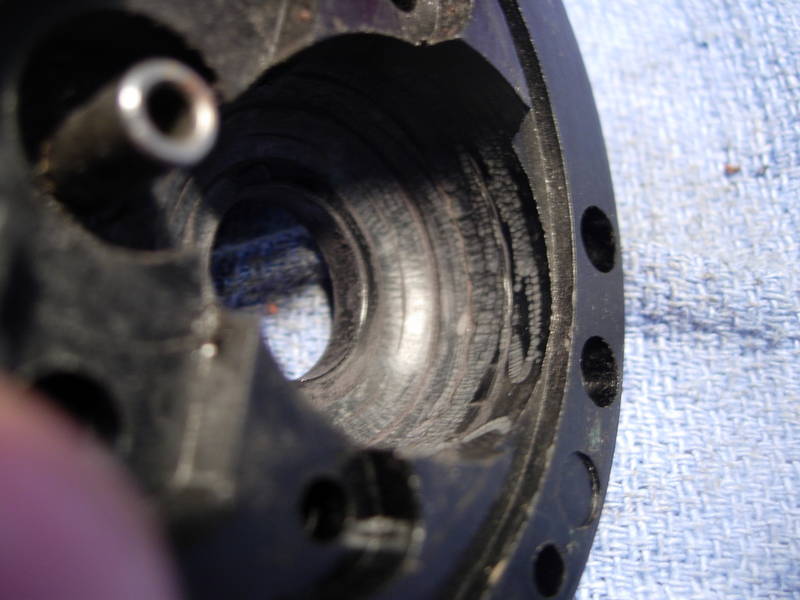

Now, we're going to have to do a little more modification then is required for the typical reel. A note of caution here. we will grinding away at the inside of this old, brittle, plastic side plate. I've done this plenty of times and have had no problems. Your results may vary. see these three steps? they need to be ground down and rounded off a little.

The dremmel and a round bit will do the job very nicely. compressed air makes the clean up quick.

Here are the final results.

There is now just barely enough clearance for the main gear and metal washers when it is under no pressure from the star.

Let's line everything up in order of installation.

First, note that you have upper bridge screws (key #17) that are only partially threaded, and lower bridge screws (key #16) that are threaded the entire length.

Install the bridge screws.

Cover the bridge screws with your index and middle fingers. hold the right side plate between your thumb and ring finger. Your pinky sticks out because this is a high class joint catering to high class people.

NOTES BY MizMo: Easier than holding the screws in place with your fingers.

Using removable scotch tape (Magic Tape), tape over the bridge screws on the outside to hold them. This frees up your hands to work on the inside parts. MUST be removable tape.

Now you can flip the side plate upside down and not worry about the screws falling out.

Install the clutch springs (key #18) on the upper bridge screws. This is the reason the screws are not threaded the entire length.

Install the pinion yoke (key # 12) and pinion gear (key #13) as a unit.

Install the eccentric jack (key #11).

Install the bridge/main gear assembly and turn it 90 degrees counterclockwise.

Push down with your thumb and install the dog (key # 15).

Now turn the bridge clockwise until it covers all but half of the last lower bridge screw.

OK, here's the million dollar trick to installing the dog spring. See the gap?

Lay the dog spring inside the gap.

Now push the dog spring down into the gap. careful here. If you miss, the dog spring could fly off into never never land. You did order a couple of back ups, right?

NOTES BY MizMo: Here is another place where removable tape can help you.

Using removable scotch tape (Magic Tape), tape over the dog and spring once you have them positioned. Then when you rotate the bridge into position, gently slide out the tape. MUST be removable tape.

OK, it's in. now rotate the bridge that last few degrees until you hear a "click" and the bridge is in it's proper position.

With a right hand assist, flip the side plate over and start each screw half way.

Now tighten down each bridge screw.

<

<

Done! You've just rebuild the right side plate of a penn 111. Oh yeah. You can breathe now....

Install the spacing sleeve (key #9).

Install the star (key #10).

Put a drop of corrosion x in the left side bushing (key #40).....

... And the right side bushing (key # 26).

Install the spool (key #29).

Install the right side plate assembly and screws. remember, one is short.

Adjust the left side bushing (key #40) until you have zero load and zero free play.

Watch it spin!!!!!!!!!!!!!!!!

Install the handle (key #24). in this case, it's a #24-56 jigmaster power handle.

Install the handle screw (key #23).

Install the handle lock screw (key #23a).

Lube the handle.

.... And done! for general maintenance, my recommendation is to strip off all the line after every trip. Yes, you read that correctly. line is cheap. Get rid of the old stuff. rinse the reel with fresh water, shake it out, dry it, respool it and reset the drag. If the freespool slows down, back out both bushings, clean them with a Q-tip, lube them with Corrosion X and reinstall then. If needed, order up new bushings. they are also very cheap. This particular reel benched out at 15 pounds. more than enough for our local salmon. It should hold up for a very long time.

Copyright © Alan Tani Reprinted with permission of the author.

Order parts online for this reel(s):

https://www.mysticparts.com/PennParts/Conventional.aspx#SenatorFamily

0 Comments