Copyright © Alan Tani Reprinted with permission of the author.

Copyright © Alan Tani Reprinted with permission of the author.

penn makes a nice series of graphite reels. they're light,they've got plenty of drag range, and they're very easy to service.here's a link to the schematic.

https://www.mysticparts.com/Assets/images/pennparts/schematics/525magt.pdf and order parts here: https://www.mysticparts.com/PennParts/Penn525MAGT.aspx

and here is our reel.

start by removing the left side plate screws (key #'s 32 and 110).

note that you have two long screws at the 3 and 9 o'clock positions (key #32) and one short screw at the 6 o'clock position (key #110).

remove the left side ring (key #28).

remove the left side plate (key #27).

here's an inside view of the left side plate, showing the magnet.

remove the spool assembly (key #29L).

here's a quick glance inside the frame (key #183).

we're going to take a moment to clean up the frame a little.

now, back to the spool.remove the spool spindle (key #71L).

remove the clutch plate retainer (key #71C).

remove the clutch plate (key #71B).

remove the right spool bearing (key #55).it measures 0.185 x 0.375 x 0.125 inches.

remove the shields from this bearing, clean it with carb cleaner and compressed air, and lube it with xtreme reel +.for a full discussion of bearing maintenance, go to http://alantani.com/index.php?topic=13.0.

i've seen some spools with alot of corrosion on the ends.clean up the spool an old toothbrush and leave a light coat of grease on it to prevent corrosion.

install the right spool bearing (key #55).

install the clutch plate (key #71B).

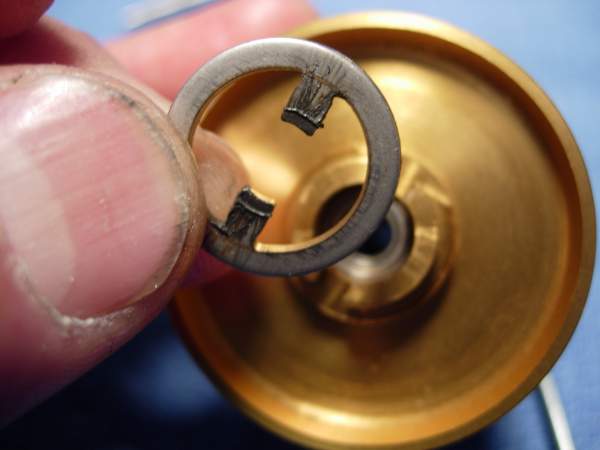

install the clutch plate retainer (key #71C).you know, that retaining ring doesn't look like it's got a very good grip.

let's flip the clutch plate over and reinstall the retainer.

there, that looks like the ring has a better grip.

use a flat screwdriver to CAREFULLY lift up the click ratchet (key #81).please do not break this.if you have two screwdrivers, place them at 180 dregrees, turn the blades clockwise and lift both sides simultaneously. i just can't do this and take a picture at the same time.

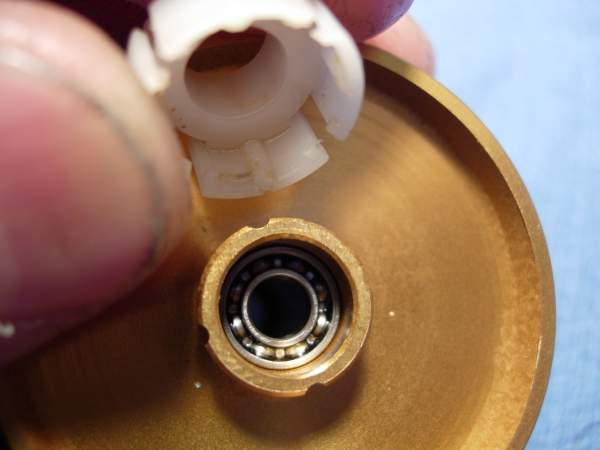

remove the left side spool bearing (key #55).this bearing also measures 0.185 x 0.375 x 0.125 inches.

clean, lube and reinstall this bearing (key #55) in the same way.

before you install the click ratchet (key #81), match up the grooves.

install the spool spindle (key #71L).

now give it a spin.using the stock abec 5 bearing, shields remove, clean and lubed with xtreme reel +, this bare spool spun for 2 minutes and 25 seconds.and that was without holding a beer in my left hand!

install the spool assembly (key #29L).

take a moment to grease the screw holes.

install the left side plate (key #27).

install the left side ring (key #28).

install the two long left side plate screws (key #32) and the one short left side plate screw (key #110).

now spin the spool.with the magnet backed all the way off, the spool spins for only 8 seconds.with the magnet cranked all the way in, freespool drops to 3 seconds.

now for the right side plate.remove the handle lock screw (key #32A).

remove the handle lock (key #110A).

remove the handle nut (key #23) using a 7/16ths wrench.

remove the handle (key #24).

remove the tension spring washer (key #8).i usually throw these away.they tend to cause corrosion.

remove the star drag (key #10).

remove the tension spring washer (key #18).

remove the two right side plate screws (key #32).

push the eccentric lever (key #21) straight up.

remove the right side ring (key #2).

this is someone's idea of a joke.there is a small right side plate screw (key #39S) hidden underneath the right side ring (key #2).

remove the right side plate screw (key #39S).

remove the two lower right side plate screws (key #46).

remove the right side plate assembly (key #1).

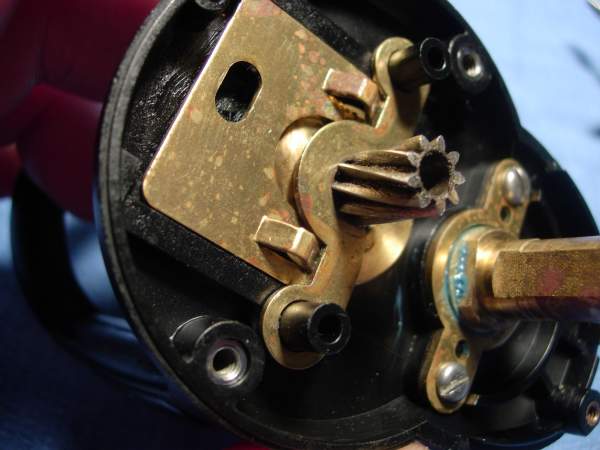

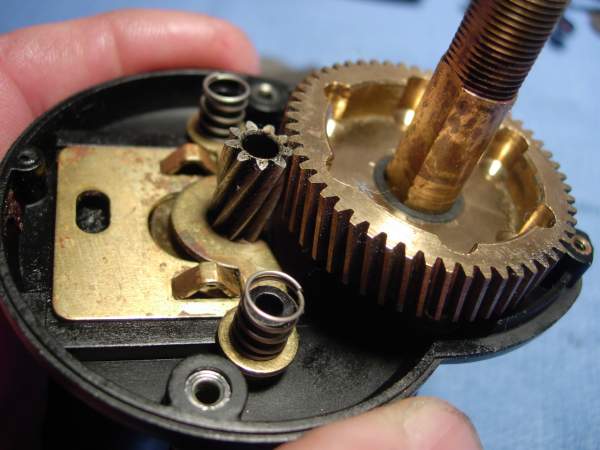

take a moment to check out the gear stack.we've got a stainless steel pinion gear and a brass alloy main gear.it also has a stack of three drag washers that functions as a traditional stack of five.

remove the clutch shaft (key #98S).

remove the entire drag stack as a unit (key #'s 5, 6 and 7C).

remove the fiber washer (key #4).

remove the ratchet spacer (key #98R).

remove the two clutch springs (key #18B).

remove the pinion gear (key #13) and the pinion yoke (key #12) as a unit.

remove the eccentric jack (key #11).

remove the two bearing retainer screws (key #63).

remove the gear stud (key #134) and bearing (key #20A) as a unit.this bearing measures 8 x 16 x 5mm.

insert the top of the gear stud (key #134) into the hanlde (key #24) so that you have something to hold on to and remove the bearing screw (key #121).

remove the shields of this bearing (key #20A), pack it with grease and replace the shields.

reinstall the packed bearing (key #20A) and the bearing screw (key #121).

well, now we have a problem.we need to pack the pinion bearing (no key #) with grease. to get to it, we will have to back track and remove the spool.

with the spool removed, the pinion bearing (no key #) taps out easily.it measures 8 x 12 x 2.5mm. the bearing should be cleaned, packed with grease and reinstalled.

ok, we are NOW ready to put everything back together.

install the gear stud (key #134), bearing (key #20A) and screw (key #121) as a unit.

install the bearing retainer (key #173).

install the bearing retainer screws (key #63).

install the eccentric jack (key #11).

install the pinion gear (key #13) and pinion yoke (key #12) as a unit.

install the clutch springs (key #18B).

install the ratchet spacer (key #98R).

we are going to replace the fiber washer (key #4) with a penn ht-100 #6-113 drag washer.

slap a thick coat of cal's grease on the washer before installing it.don't worry about the excess grease.it will simply squeeze out the sides.

install the main gear (key #5).

slap a thick coat of cal's grease on the three drag washers (key #6).

install the drag washers (key #6) alternating with the metal washers (key #7C) and the clutch shaft (key #98S).

i almost forgot about the right side plate bearing (key #55A).this bearing measures 0.125 x 0.375 x 0.156 inches.this bearing can be difficult to open and pack, so we're going to just lube it with corrosion x and keep out fingers crossed that it does not corrode.lube the anti-reverse roller bearing with corrosion x as well.

put a small bead of grease in the screw holes of the frame (key #183).

flip the eccentric lever (key #21) forward and install the right main side plate (key #1).

install the two lower right side plate screws (key #46).

install the small right side plate screw (key #39S).

move the eccentric lever (key #21) to the center and install the right side ring (key #2).

install the two right side plate screws (key #32).

install the tension spring (key #18).

install the star drag (key #10) and turn it down until it clears the shoulders of the gear stud (key #134).

remember the tension spring washer (key #8)?all it does is cause corrosion, so we are going to throw it away.

install the handle (key #24).

install the handle nut (key #23).

install the handle nut lock cap (key #110A).

install the handle lock screw (key #32A).

install the spool assembly (key #29L).

install the left side plate (key #27) and left side ring (key #28).

install the left side plate screws (key #'s 32 and 110).

congratulations, you're done!

well, almost.no rebuild would be complete without the signature handle upgrade.here's the same reel with a chromed arm and a 4/0 kolekar grip.

ok, now we're done!

Copyright © Alan Tani Reprinted with permission of the author.

Order parts online for this reel(s):

https://www.mysticparts.com/PennParts/Conventional.aspx#MAG

0 Comments