|

|

To Reduce How Often A Reel Needs Repair MAINTENANCE Is The KEY!

Always rinse off your equipment when you get back to the dock, especially the rod guides and the reel. Don't use full force on the hose when cleaning off the reel...if you were in the surf this will blast sand into the interior of the reel. If necessary, remove the spool on spinning reel so that you can rinse underneath.

Allow everything to dry or wipe it down with a cloth. Spraying the exterior of the reel with WD40 or equivalent will help to prevent rusting/corrosion from saltwater. DO NOT get any spray on the fishing line. Best to spray conventional's down in between line changes. We also use WD40 to soak reels or parts to clean them prior to a full clean/lube. Do NOT soak sealed bearings, they are almost impossible to regrease without damaging. Open bearings you can relube.

Lubes and Greases

Periodically apply reel lube or grease to gears and pinions. Make sure to use only products that are designed for use in fishing reels, as other lubricants can harden over time and bind up your reel. Be careful not to over grease, it's not necessary to load up the inside of the reel with grease and it can cause problems later on. Do not grease the anti-reverse dog, it causes it to slip and/or binds up the spring.

To Grease Drags, or Not To Grease Drags

Penn designed their HT100 drags to run dry, but they can be used (angler's option) with a VERY THIN coating (which is then wiped off) of drag grease.

Types of Drag Greases:

- Shimano makes a drag lube - we don't carry it at this time.

- Penn hasn't come up with an equivalent yet.

- We do carry Cal's Universal Reel and Star Drag Grease, you can find it in the Lubes/Greases section of our online catalog in the PennParts Dept.

What Parts Generally Need Replacing?

Each reel can wear differently depending on how heavily it is used. You won't know what you need to replace until you take it apart and look it over.

Basic things to look for in each reel:

- Drags and Springs - wear/tear

- Bearings - do they still turn smoothly

- Screws - lost or damaged

- Gears - check all teeth

- Ratchets and Dogs - excessive wear/rounding of edges.

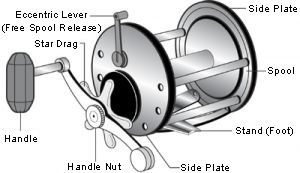

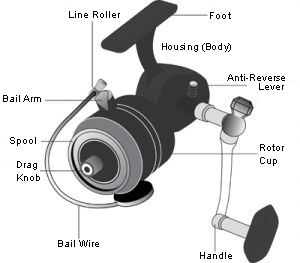

Basic Reel Construction Terminology

|

|

2 Comments