WORK IN PROGRESS 5/16/19

|

By Maureen Albertson |

A breakdown of the SSV10500 as a sample to help with re-assembly of these reels. TOOLS: Standard and phillips head screwdrivers, adjustable or socket wrench, micro phillips screwdriver size PH0, tweezers.

- Quick jump to specific parts:

- Bail Spring and Trip

- Clicker, Spool

- Clutch (Anti-Reverse) and Pinion Gear

- Drag Washers

- Gears, Main and Crosswind

- Line Roller Assembly

- Lever, Cam and Spring

- Rotor and Spool Shaft

- Trip Lever Assembly in Cover

Or just start reading from here:

DESIGN CHANGE #1: HOUSING & CROSSWIND GEAR

They changed the inside diameter of the crosswind gear and the size of the corresponding pin on the housings of several of the SSV reels. More notes about the design change here: https://scottsbt.zendesk.com/hc/en-us/articles/204309045-SS-Reels-SSV-Gear-Design-change

NOTE: The #231A screw in the center of the #231 crosswind gear will strip easily! Needs a micro phillips head size PH0 to remove it.

Start by removing the drag knob and spool and setting those aside. Remove the housing cover so that you can access the gears and remove the shaft to get under the rotor if needed.

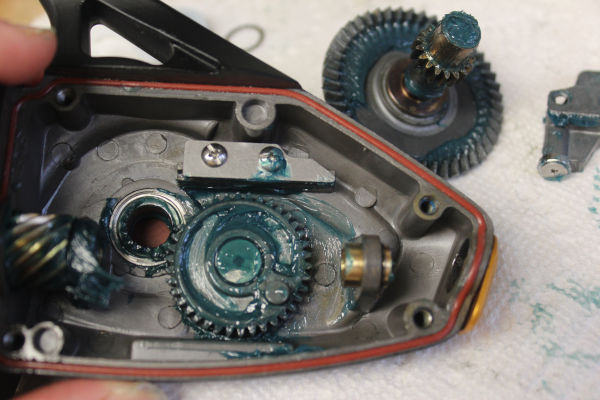

Here, the #43 crosswind block has been removed and the #39 shaft pulled out. Main gear is out and set aside.

ROTOR AND SPOOL SHAFT

To access the clutch, pinion gear and bearings, first you have to remove the rotor. Unscrew and remove the #43A osc. slider glide (AKA crosswind block plate) inside the housing. This style has two hooks on it the fit against the shaft on either side of the #43 osc. sl(AKA crosswind block).

Under the rotor, starting position of levers.

Under the rotor lever removed.

Positioning of the parts in the white lever.

#5 spring positioning on the black lever #4 and the #10 pin.

Seating of the #4 lever and #5 spring on the #1 housing. The tab under the #4 sits in the groove on the housing. The bottom leg of the #5 spring shown sticking out in the bottom right corner of the image, has to be tucked over on the other side of that wall behind the little tab that sticks up. This puts the tension on the lever. Finally photo will have an arrow and some notes on it.

CLUTCH (ANTI-REVERSE) AND PINION GEAR

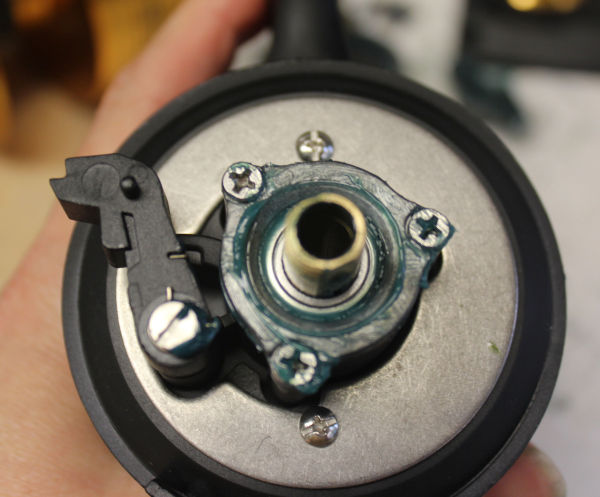

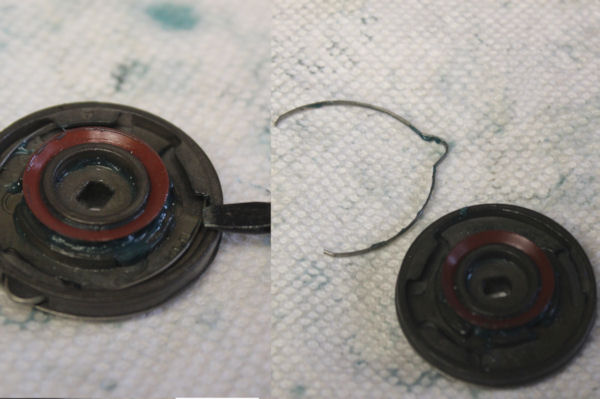

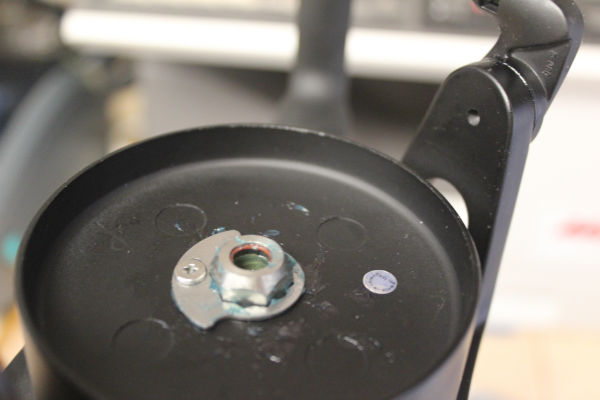

Under the rotor, you can access the anti-reverse clutch, pinion gear and bearings. Remove the #21A screws and #21 bearing cover.

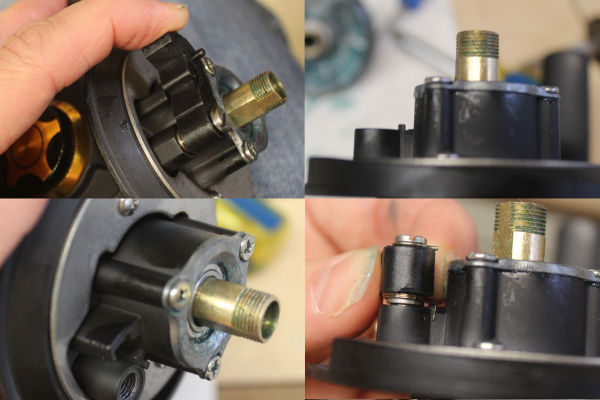

Slide out the assembly.

Inspect #20B AND 20AB bearings for smoothness. If only slightly rough, keep them for another season. If you cannot spin the bearings or they are extremely gritty, it's time to replace them.

Check the teeth on the gear and make sure there are no cuts in the #21B collar that would make the reel sound rough.

If the anti-reverse has been malfunctioning, make sure the interior of the #98 clutch is clean and all of the small pins are in place. If you reassemble the reel and the a/r is still failing, it's time to replace #98.

NOTE: TOO MUCH GREASE WILL MAKE A/R FAIL, do not grease the inside.

Putting the pinion assembly back together, washer placement 8A

************************************ WORKING ABOVE THIS LINE ************************************

*************************************************************************************************

USING the SSV6500LL pics below this point

3/23/2025 Missing some SSV10500 pictures, not sure if not taken or just misplaced the file. JUST NOTES BELOW THIS POINT from the SSV6500ll guide that I made but still helpful here even without pics. ~More

BAIL SPRING AND TRIP INSTALLATION

This work is done with the #24 bail in CLOSED position.

LEFT: Underside of the #27 rotor showing the tip of the #28 bail trip lever.

RIGHT: the #27A rotor cover. Remove the small #22 screw to access the #32bail spring.

(((SSV6500LL size pictures here)))

TOP: The #32 bail spring, #34C pivot arm and #28 bail trip lever.

MIDDLE: Connection of the #34 bail arm, notes in photo.

BOTTOM: Installation of the pieces. The #34C should be place so that the little upward arm fits in the hole in the #34 bail arm.

(((SSV6500LL size pictures here)))

LINE ROLLER ASSEMBLY

LEFT: Line roller assembled in the #34 bail arm and #24 bail wire.

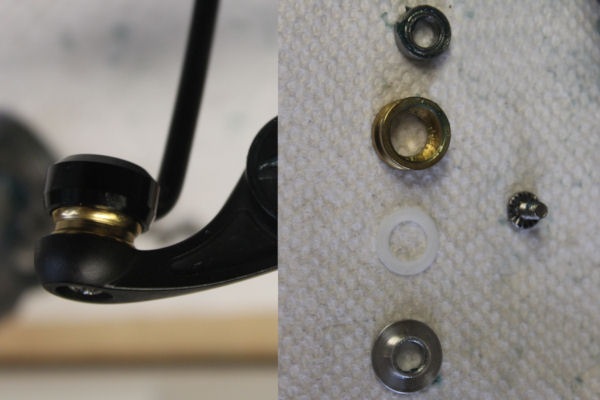

RIGHT: Top to bottom as positioned in the left photo. #35A bearing goes into the #35 line roller, then the white #132A washer sits between the line roller and the #132 line roller washer. The number #36 screw goes into the bail arm and through the #35 line roller to screw into the seat on the #24 bail wire.

(((SSV6500LL size pictures here)))

DRAG WASHERS AND SPOOL ASSEMBLY

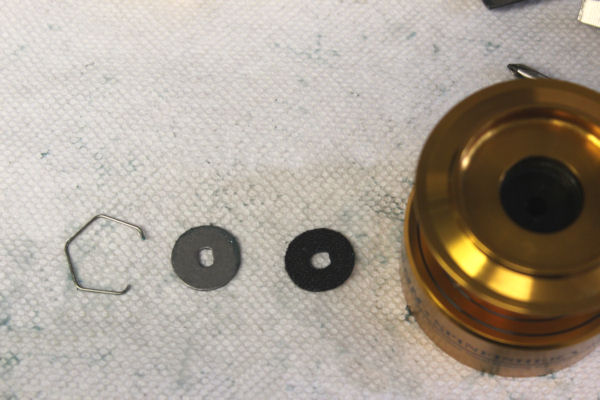

Upper part of the spool, the order of the washers. For the purpose of this walk-thru, I did NOT remove the #63 spool bushing, which remains inside the top of the spool. The #56T HT100 fiber washer goes into the spool first, the the #57T keyed metal washer, then the #51 retaining spring sets into the groove in the top of the spool to lock them in place.

(((SSV6500LL size pictures here)))

The underside of the spool. Note the positioning of the #47F line clip retainer, which is held in place on the lip of the #47C drag cover by one of the small #22A screws (micro phillips head screw driver size PH0 required). The #47D line retainer post goes through the #47E bushing, through the hole in the side of the spool. The #47F line clip retainer goes through the small hole in the side of the 47D post as shown above.

(((SSV6500LL size pictures here)))

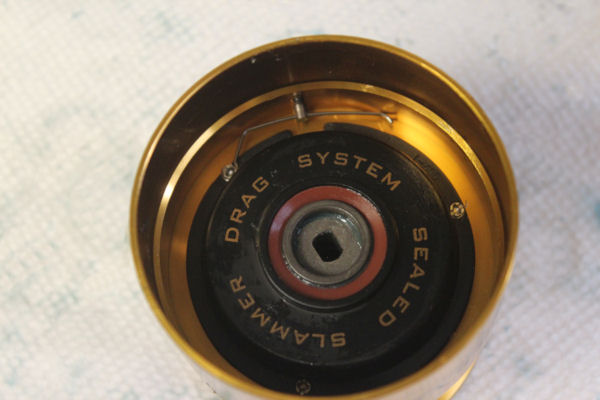

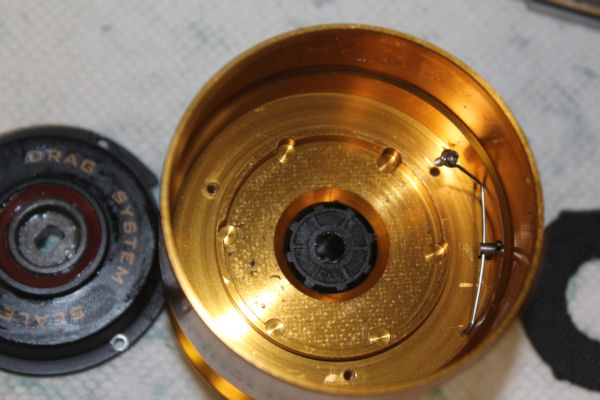

Unscrew the 3 #22A screws (micro phillips head screw driver size PH0 required), to access the lower spool drags. Note that the #48S red drag cover seal will probably jump out of place. Set it aside for the moment. You can see the notches where the drags sit in the spool.

(((SSV6500LL size pictures here)))

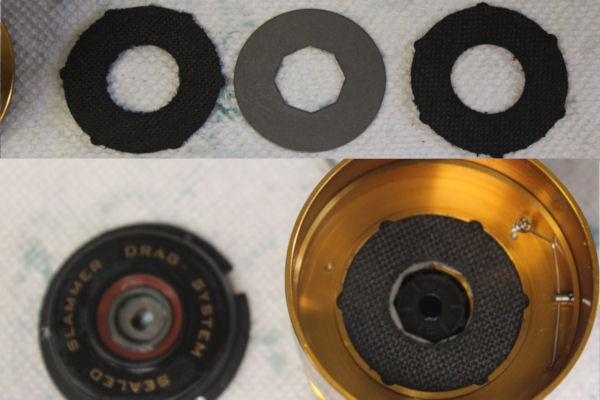

The order is simple. A #56 HT100 drag washer goes in first, then the #57 metal washer then the second #56 washer. In these photos, the second #57 metal washer is still connected to the #117 drive plate and is not shown.

(((SSV6500LL size pictures here)))

The #48S drag cover seal sets into the #47C drag cover as shown to the right here. The #117 is upside-down in this photo so that you can see the #47S drive plate seal installed on it, and the #48 spool clicker inside it. You would then flip it over into the #47 cover to reassemble.

(((SSV6500LL size pictures here)))

Removing and re-installing the #48 spool clicker is fairly simple. Just use the tip of the screw driver to pop one arm loose, then grab the looped end and slide it out of the #117 plate. Put it back in the same way.

DRAG ASSEMLBY TIP: I found it easier to stack all of the bottom spool drags into the 47C cover, hold the spool in one hand and bring the stack up from underneath to set it in place in the spool, then turn it all over to screw the cover down again.

(((SSV6500LL size pictures here)))

Removing the spool bushing is done after taking off top and bottom drag washer systems. Push the bushing up from the underside of the spool using level pressure with a screw driver handle. Reinstall it from the top as shown. Center the bushing and push straight in using screw driver handle with level pressure until it stops.

Order parts online for this reel(s):

https://www.mysticparts.com/PennParts/Spinning.aspx#SS5thGen

0 Comments